At the moment, only 14% of global plastic packaging is collected for recycling and only 2% is reused

Image: REUTERS/Enrique Castro-Mendivil

27 Oct 2016, James Pennington, Project Specialist, Circular Economy, World Economic Forum

Plastic is the workhorse material of the modern economy. Lightweight and durable, it’s been used to make a vast number of products since its introduction over 100 years ago.

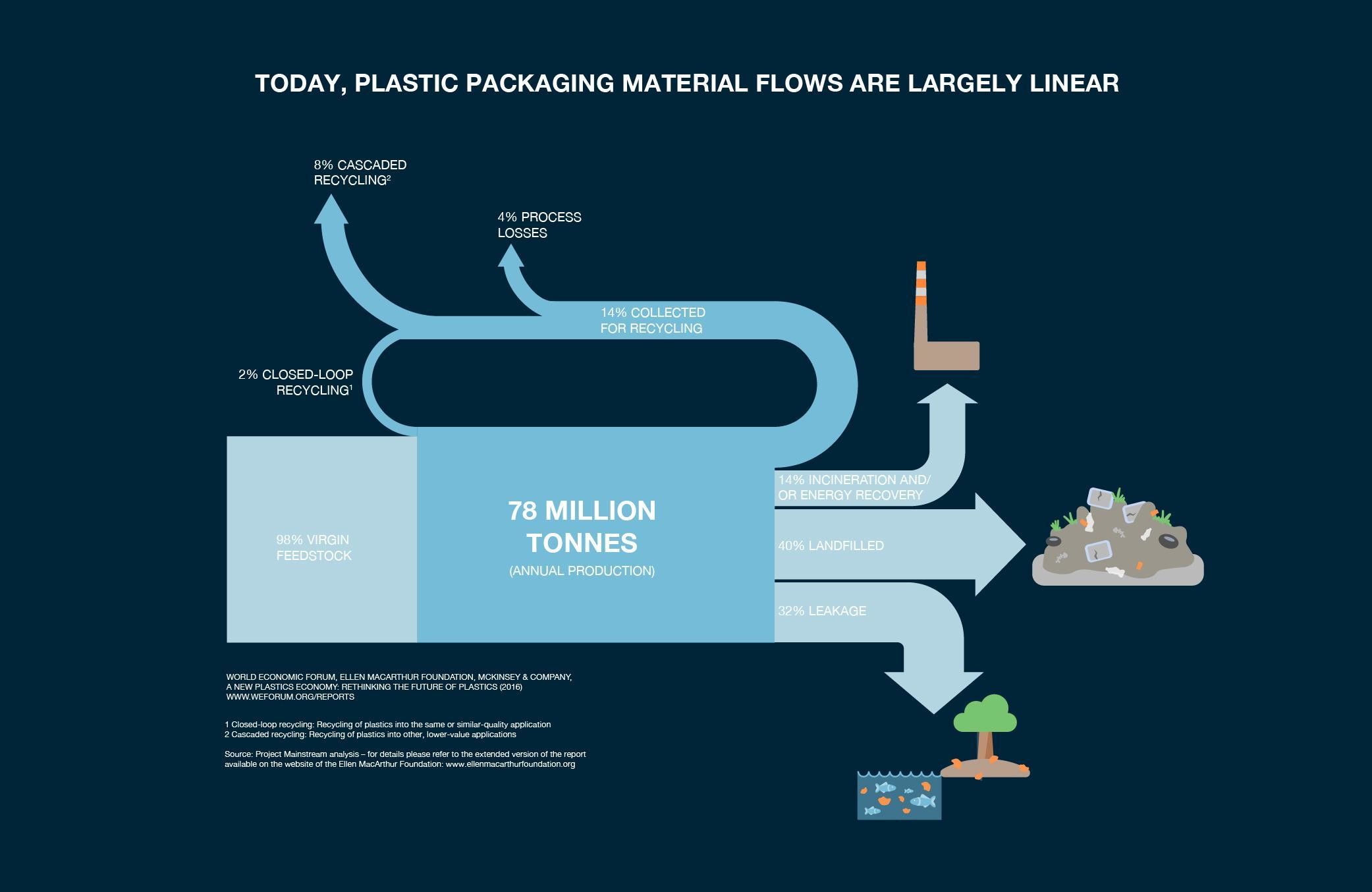

However, a study undertaken by the World Economic Forum, the Ellen MacArthur Foundation and McKinsey and Company showed the scale of the breakdown in the global plastic system. A full 32% of the 78 million tons of plastic packaging produced annually is left to flow into our oceans; the equivalent of pouring one garbage truck of plastic into the ocean every minute.

If we carry on as usual, this is expected to increase to two per minute by 2030 and four per minute by 2050. By 2050, this could mean there will be more plastic than fish in the world’s oceans. At the moment, only 14% of global plastic packaging is collected for recycling and only 2% is reused as packaging. In total, $80-$120 billion of value is lost annually. The system needs to change and there are a number of people working to make this happen.

Taking plastic out of the ocean

The Ocean Cleanup, a start-up founded in 2013, is the brainchild of Boyan Slat, who conceived the idea for the company when he was just 17 years old. Since then, it’s received more than $2 million in funding.

The company plans to use a large array that will be anchored to the bottom of the Pacific Ocean. This will have arms that spread out over 100km, capturing all of the plastic debris pushed into its nets. This is then collected by a giant container with a 10,000-metre-cubed capacity that will be emptied monthly. The system is passive - it uses the ocean current to push the plastic towards it making it cheap and efficient. As it says on the company website, “Why move through the ocean, if the ocean can move through you?”

The team behind the project thinks they can clear 70 million kg of plastic out of the Great Pacific Garbage Patch in 10 years at a price of 4.53 euros a kilo.

Have you read?

“Taking care of the world’s ocean garbage problem is one of the largest environmental challenges mankind faces today. Millions of tons of plastic have entered the oceans, damaging ecosystems and entering the food chain. Although it’s essential to prevent more plastic from entering the oceans, the plastic that’s already trapped in the currents of the oceans doesn’t go away by itself,” says founder Boyan Slat.

Most recently, The Ocean Cleanup launched an aerial expedition aboard a specially modified C-130 Hercules aircraft laden with specialized sensor equipment. It discovered that the problem was worse than expected with an abundance of plastics measuring up to 1.5m across and at a higher density than previously thought. The organization will continue to pilot the array and will start cleaning the patch before the end of the decade.

Once the plastic is out, what should we do with it?

The foundation hopes that the plastic from the ocean will have a commercial value which can help to fund the project. Ocean plastic is not easy to use, it’s heterogeneous by nature consisting of everything from intact PET bottles to micro plastics. However, some of the world’s biggest companies also see the opportunity to market oceans plastic products.

For example, Adidas in partnership with the organization Parley For the Oceans, has created a shoe made from ocean plastic. It uses a combination of PET bottles and nylon fishing nets. The shoes are built to the same standards as any other pair of Adidas trainers and the company believe the ecological benefits of using ocean plastics will attract consumers. The first production run is only 50 pairs and the process is still relatively expensive (including removing the smell of fish) but the companies believe this prototype can pave the way for a new category of consumer items. Others have joined in making beautifully designed products from tables to beach huts.

How do we keep plastic out of the ocean in the first place?

We now use 20 times more plastic than we did in 1964, and this shows no sign of slowing. The majority of this comes from “virgin stocks” (crude oil), with only 2% of the plastic packaging used globally coming from recycled sources. A certain amount of alignment in the system could go a long way.

The Ellen MacArthur Foundation has launched an initiative that will aim to close this gap. The New Plastics Economy Initiative brings together all of the major players in the field from plastic manufacturers to retailers and recyclers to create a common plastics protocol, which will make plastics easier to recycle; as well as launching a series of innovation moonshots including inventing a material which has all the properties of plastic but is able to dissolve safely in water.

Although the best system is a closed loop system, in which plastic bottles are re-made into other plastic bottles, another important way of improving the economics of plastic recycling is through upcycling. Musician Pharrell Williams is lending his star power to the cause and has teamed up with the clothing brand G-Star to create ‘bionic yarn’, a fabric made from PET bottles.

The stated aim of the fabric is not just to stem the amount of plastic in our oceans, but also to educate consumers. The t-shirts display statements such as “happy oceans happy life” and the founders say that sustainability is core to the brand. Other companies such as McDonough Innovation, and Taiwanese firm Miniwiz have also found durable uses for plastics in the form of building materials and other products.

Williams, the co-founder of Bionic Yarn, said: “When we have water, that’s when you know that you have life. When that is contaminated you don’t have anything … we can slow down the production of new polyester, we can just recycle the plastic from bottles."

What if we used something else?

One way to stop plastic leakage into the ocean is by replacing it with a different material. In India, 120 billion pieces of plastic cutlery are disposed of annually. In response to this startling amount of waste, an Indian startup called Bakeys has come up with an edible alternative.

Their brand of edible spoons, knives and chopsticks are baked rather than manufactured, and even come in a number of different flavours including celery, black pepper and cumin. If you don’t like the taste, then the cutlery will safely biodegrade in just five days. The company launched a kickstarter campaign which raised over $250,000, well above the initial target of $20,000. They have now invested in a new production line and shipped over 3 million items. The founder believes that with scale, the edible spoon will soon cost the same as the plastic alternative. “So now the cutlery is tasty, fun, nutritious and environmentally friendly,” said the founder Narayana Peesapahty.

Transforming today’s plastics economy from its current form (take-make-waste) to a zero waste circular economy (take-make-take-make) is a daunting challenge. However, with coordinated action from producers, recyclers, governments and consumers alike and continuing innovation in the sector – it can be done.

Đăng nhận xét